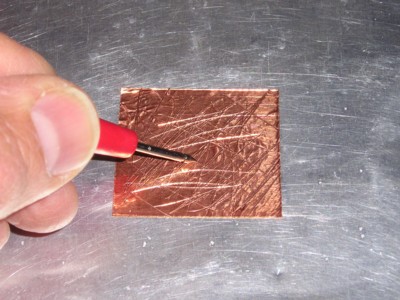

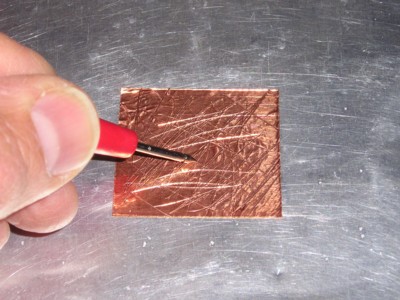

Figure 1. Measuring the Resistance from Copper Foil Tape to Chassis Metal

Abstract: Copper foil tape is very

useful for quick circuit board changes, shielding fixes, and many

other uses around the lab. Sometimes a low resistance connection

between the foil and the underlying metal is necessary. A simple

technique is described to help insure a low resistance connection.

Discussion: Figure 1 shows an Ohmmeter being used to check the resistance between a piece of copper foil tape and chassis metal to which the foil is applied. Even if the foil tape has "conductive adhesive," there may still be a significant resistance between the copper foil and underlying metal in some cases.

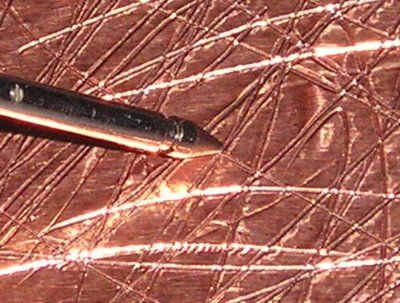

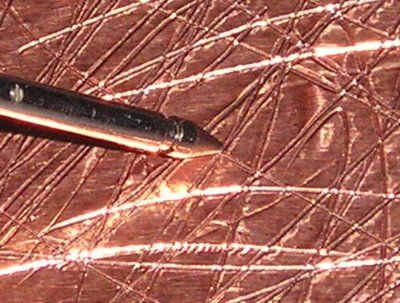

A simple solution to the problem is shown in Figure 2. In this case, the sharp point of the Ohmmeter test probe is used to score the surface of the tape so as to break through the adhesive and help insure a good connection to the underlying chassis metal. Figure 3 shows a close-up of the surface of the tape after the scoring. Even though the copper foil tape used for this article did not have conductive adhesive, the Ohmmeter in Figure 1 shows that a low resistance between the foil and the chassis metal was achieved.

Figure 2. Scoring the Surface of the Tape to Achieve Low Resistance to the Chassis

Any sharp object can be used to score the surface of the tape. In a pinch, even a fingernail can be used. When measuring resistance between the foil tape and underlying metal, be careful not to push on the Ohmmeter probes with too much force especially if the tips are sharp. The tips may break through to the metal directly giving a low resistance reading that is not correct or the probe tip may connect the tape to the metal in only the spot where the resistance was measured.

A low resistance connection is not necessary in all instances. There is a lot of capacitance between the foil tape and the chassis metal as far as high frequency currents are concerned. At hundreds of megahertz and higher, the capacitance between the tape and underlying metal may be all that is necessary in some applications. For the cases where the resistance must be low, the technique shown here can be used to help insure a low resistance connection from the foil tape to underlying metal.

Summary: Scoring the surface of copper foil tape with a sharp object is a simple way of reducing the resistance between the foil tape and the metal it is applied to.

Discussion: Figure 1 shows an Ohmmeter being used to check the resistance between a piece of copper foil tape and chassis metal to which the foil is applied. Even if the foil tape has "conductive adhesive," there may still be a significant resistance between the copper foil and underlying metal in some cases.

A simple solution to the problem is shown in Figure 2. In this case, the sharp point of the Ohmmeter test probe is used to score the surface of the tape so as to break through the adhesive and help insure a good connection to the underlying chassis metal. Figure 3 shows a close-up of the surface of the tape after the scoring. Even though the copper foil tape used for this article did not have conductive adhesive, the Ohmmeter in Figure 1 shows that a low resistance between the foil and the chassis metal was achieved.

Figure 2. Scoring the Surface of the Tape to Achieve Low Resistance to the Chassis

Figure 3. Close-up of Scoring Marks on the Foil Tape

Any sharp object can be used to score the surface of the tape. In a pinch, even a fingernail can be used. When measuring resistance between the foil tape and underlying metal, be careful not to push on the Ohmmeter probes with too much force especially if the tips are sharp. The tips may break through to the metal directly giving a low resistance reading that is not correct or the probe tip may connect the tape to the metal in only the spot where the resistance was measured.

A low resistance connection is not necessary in all instances. There is a lot of capacitance between the foil tape and the chassis metal as far as high frequency currents are concerned. At hundreds of megahertz and higher, the capacitance between the tape and underlying metal may be all that is necessary in some applications. For the cases where the resistance must be low, the technique shown here can be used to help insure a low resistance connection from the foil tape to underlying metal.

Summary: Scoring the surface of copper foil tape with a sharp object is a simple way of reducing the resistance between the foil tape and the metal it is applied to.

Other articles on this website related to this topic are:

Additional Material: An in-depth audio-visual format tutorial on this subject, covering background as well as more technical details, is available at: http://emcesd-p.com.

If you like the information in this article and others on this website, much more information is available in my courses. Click here to see a listing of upcoming courses on design, measurement, and troubleshooting of chips, circuits, and systems.

Available now for private on-site delivery and as a public seminar: my new one day seminar titled: Failure Analysis and Prevention in Electronic Circuits (Design Troubleshooting for the Lab and Field).

Top of page

Home