Figure 1. Mating Connectors or System Modules May Cause an ESD Event With Adverse Effects on the System

Abstract: Electrostatic

Discharge (ESD) can cause electronic system malfunction or even damage

to circuits. The use of static dissipative materials in system

construction can eliminate many ESD events, This subject has been

talked about in technical circles for years now and is the topic of

this Technical Tidbit article. A new patent is referenced that was

recently issued and describes just such an approach to connector

design.

Discussion: Figure 1 shows two

mating connectors in close proximity. Mating two system components can

result in an ESD event with unwanted effects on the system including

damaging sensitive components. There are two ways of handling such a

scenario. One is to design the equipment to withstand the ESD event or,

alternatively, prevent the ESD event from happening in the first place.

The second approach is the subject of this Technical Tidbit.

There are many examples of ESD events happening when system modules or connectors are mated. One famous example involved a personal digital assistant, PDA, which when placed in its dock to synchronize with the host computer, resulted in an ESD event between the PDA and the dock. The ESD current traveled down the serial cable from the dock to the computer and damaged the serial port chip in the host computer. This type of ESD event is likely to happen when any device is placed in a docking station for charging or data transfer. Other examples include cordless phones, media players, and cellphones.

People have discussed for years how to suppress these ESD events including using static dissipative materials in the housings of the devices and docking stations. The idea is to drain the static charge in milliseconds instead of nanoseconds so the current and its time derivative, di/dt, are not large enough to cause a problem. If a hand held device and its docking station have housings made of static dissipative materials then the charge can drain when the housings touch, before metallic contact is made between the connectors. The trick is to have enough conductivity in the housing to drain the charge in the time available between when the housings touch and when the connectors touch. Too little conductivity and the static charge will not have enough time to drain and too much conductivity will allow a spark with its resulting high peak current. Static dissipative materials come in a wide variety of resistances for a given shape. The correct value of resistance needed will depend on the amount of charge to drain and the time available to drain it, usually several milliseconds.

In the past, static dissipative materials had limitations that reduced the number of applications they could be applied to. Color, useful lifetime, humidity dependency of performance, and mold wear problems are a few of these limitations. Newer materials have overcome many of these limitations. One material useful for dark colored pieces is Static Intercept™ that was invented at AT&T Bell Labs a number of years ago.

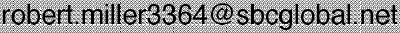

Recently, I became aware of a patent that was issued last July for a way of eliminating ESD between cable connectors. An image of a portion of the first page is shown in Figure 2. Clicking on Figure 2 will access a pdf file containing the first two pages of the patent. If you are interested in this idea, contact Bob Miller at the email address shown in the graphic below the image in Figure 2.

Figure 2. Patent Using a Static Dissipative Connector Shell to Eliminate ESD Events

(click on the patent image to see a pdf file of the first two pages of the patent)

You don't even need to have metallic contact between two pieces of metal to have an ESD event. If two pieces of metal are close but not touching, a spark can be induced between the metal pieces just by bringing a charged object near one of the metal pieces as described in my May 2001 Technical Tidbit, "Hidden Threats to Electronic Equipment" and the June 2001 Technical Tidbit, "A Static Field Powered EMI Source." In the May 2001 article, a spark was induced inside of the equipment by a static charge outside of the equipment. This type of event can be prevented by making sure all metal pieces in equipment have a conductive path between them. This can be achieved using static dissipative materials in the equipment housing as well as more conventional means using wires or resistors.

There are many examples of ESD events happening when system modules or connectors are mated. One famous example involved a personal digital assistant, PDA, which when placed in its dock to synchronize with the host computer, resulted in an ESD event between the PDA and the dock. The ESD current traveled down the serial cable from the dock to the computer and damaged the serial port chip in the host computer. This type of ESD event is likely to happen when any device is placed in a docking station for charging or data transfer. Other examples include cordless phones, media players, and cellphones.

People have discussed for years how to suppress these ESD events including using static dissipative materials in the housings of the devices and docking stations. The idea is to drain the static charge in milliseconds instead of nanoseconds so the current and its time derivative, di/dt, are not large enough to cause a problem. If a hand held device and its docking station have housings made of static dissipative materials then the charge can drain when the housings touch, before metallic contact is made between the connectors. The trick is to have enough conductivity in the housing to drain the charge in the time available between when the housings touch and when the connectors touch. Too little conductivity and the static charge will not have enough time to drain and too much conductivity will allow a spark with its resulting high peak current. Static dissipative materials come in a wide variety of resistances for a given shape. The correct value of resistance needed will depend on the amount of charge to drain and the time available to drain it, usually several milliseconds.

In the past, static dissipative materials had limitations that reduced the number of applications they could be applied to. Color, useful lifetime, humidity dependency of performance, and mold wear problems are a few of these limitations. Newer materials have overcome many of these limitations. One material useful for dark colored pieces is Static Intercept™ that was invented at AT&T Bell Labs a number of years ago.

Recently, I became aware of a patent that was issued last July for a way of eliminating ESD between cable connectors. An image of a portion of the first page is shown in Figure 2. Clicking on Figure 2 will access a pdf file containing the first two pages of the patent. If you are interested in this idea, contact Bob Miller at the email address shown in the graphic below the image in Figure 2.

Figure 2. Patent Using a Static Dissipative Connector Shell to Eliminate ESD Events

(click on the patent image to see a pdf file of the first two pages of the patent)

You don't even need to have metallic contact between two pieces of metal to have an ESD event. If two pieces of metal are close but not touching, a spark can be induced between the metal pieces just by bringing a charged object near one of the metal pieces as described in my May 2001 Technical Tidbit, "Hidden Threats to Electronic Equipment" and the June 2001 Technical Tidbit, "A Static Field Powered EMI Source." In the May 2001 article, a spark was induced inside of the equipment by a static charge outside of the equipment. This type of event can be prevented by making sure all metal pieces in equipment have a conductive path between them. This can be achieved using static dissipative materials in the equipment housing as well as more conventional means using wires or resistors.

Summary:

Reducing the likelihood of ESD events using static dissipative

materials in equipment design is possible and practical using modern static dissipative materials. Hand held devices that

utilize docking stations for charging or data transfer are a prime

examples of where static dissipative materials could be used. A new patent

was presented that covers this idea as applied to connectors.

- US Patent on Static Dissipative Connector Shell (first two pages): us007404724.pdf

- Static Intercept, an innovative material for draining static charge

- RMV Technology Group is a expert source of information on materials in general and ESD dissipative materials specifically.

Click here for a description of my latest seminar titled (now available online as a WebEx seminar):

EMC

Lab Techniques for Designers

(How to find EMC problems and have some confidence your system will pass EMC testing while it is still in your lab).

(How to find EMC problems and have some confidence your system will pass EMC testing while it is still in your lab).

Home