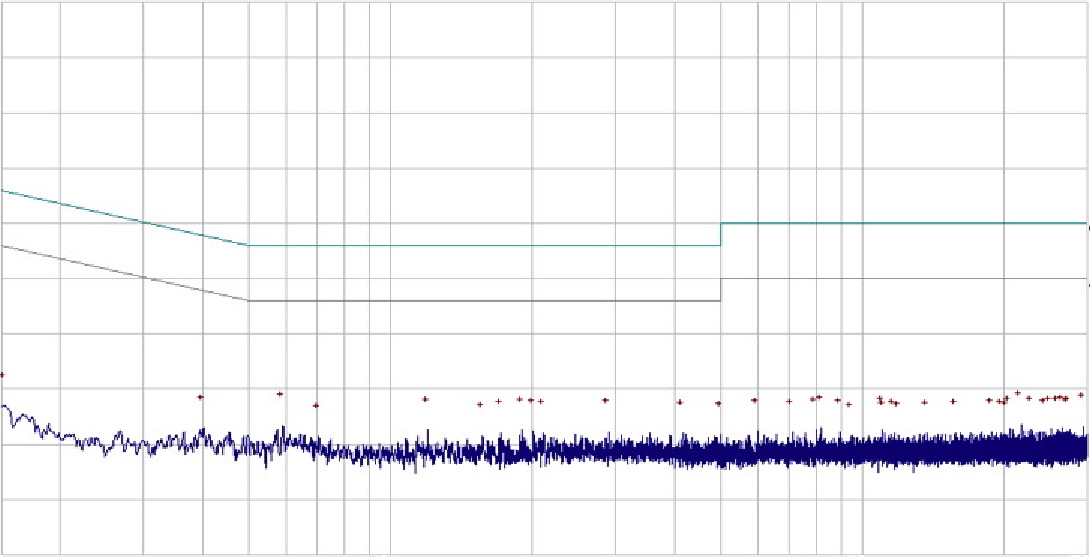

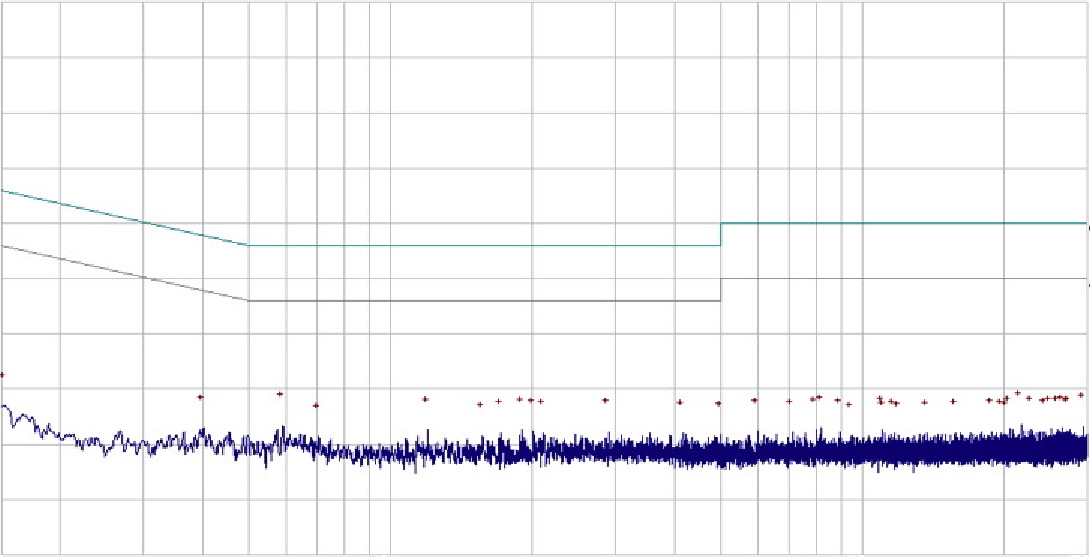

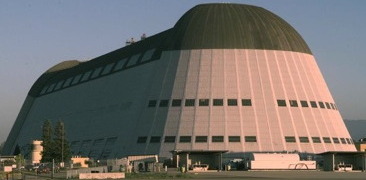

Figure 1. Suspect Data from a Conducted Emissions Test

See my one hour webinar on this topic. Click here

to see a description of the webinar. This webinar is a real "eye

opener." Lots of information and checklists for both test lab customers

and test labs to protect oneself. "Trust but verify."

Abstract: EMC testing is a

required part of bringing a product to market. Passing the test itself

can be a real headache for developers and marketers, but what if the

test was performed in error and the test results are not valid!

This is a real problem in the more general field of lab testing as well

as specifically EMC testing. Some thoughts are shared on the topic.

Figure 1 shows a conducted emissions plot that was supposed to

represent the emissions form a product on one of the two power leads

(neutral and line are the two leads) but seems to just show the noise

floor of the instrumentation. No product is or should be this quiet. If

it is, the designer spent way too much money on the design. In this

case, the other power lead had the expected emissions so it is just

about impossible for the plot above to be correct. I have a similar

plot of a radiated emissions test where the data was close to the noise

floor of the instrumentation. Given results like these, a test engineer

or technician should

immediately check to see the EUT (equipment under test) is operating as

expected and that the measurement equipment is also operating as

expected. In fact, at the beginning of each new product test, the

measurement equipment should be checked for proper operation in some

manner.

I have personally witnessed many

errors made by EMC test labs over the years. For the most part, they

did not affect me or my company at the time because the errors were spotted and corrected before they caused problems.

Sometimes there was push-back from the test lab to my suggestions,

however I prevailed in 100% of the cases. But test labs should not

expect their clients to be able to do this or in fact have any EMC

experience at all.

Currently I am helping a company who may face significant additional cost because

of a combination of miscommunication between the test lab and the

company (the test lab must have assumed the company had significant EMC

knowledge/experience) and two egregious test errors that yielded bad

data upon which the company based business commitments.

Here are just a few of many examples from my experience:

- Every test lab

where I have been present during a conducted immunity test performed

the test in error that resulted in an over test averaging about 6 dB!

They tested according to the standard, but apparently did not read the

whole standard. Just a few words missed in a test standard can result in bad testing that persists for years.

- There are a number

of ESD test tables of one design placed in companies and test labs in Silicon

Valley that do not meet the requirements of IEC 61000-4-2. They

initially do in one respect, but after a month fail in a way that can

apply much more ESD energy to the EUT! In another respect, these test

tables never complied with the IEC standard to begin with. The effect

is to affect the test outcome. I have also seen similar problems

elsewhere in test labs across the US, both private and commercial.

- I

have encountered

several labs that made errors in radiated emissions measurements as a

result of human error or equipment failure. Many labs take a short cut

on the radiated emissions test setup that can increase apparent

emissions by a few dB causing the EUT to fail when it should have

passed.

- Just

having a

current calibration sticker on test equipment is not adequate and is no

guarantee of good test data. All of the bad data I have seen was

generated on equipment with current calibration stickers. I tested

eight ESD simulators a few years ago. All had current calibration

stickers and two of the simulators were defective.

- Having current lab certifications does not avoid the above problems either.

So what is a company with

a new product to do? What should test labs do since the normal

accreditation process does not seem to catch these errors? Using a large, well

known EMC test lab does not necessarily avoid these problems either.

And although experienced test personnel are a good thing for a lab to

have, experience can actually cause certain types of errors. Just

because a test has always been done a certain way does not make it

correct! The situation is sort of like SCUBA diving. The experienced

divers are often the ones that get in the most trouble.

At

the least, ask a lot of questions of the test personnel and make sure

they understand how your equipment works and possibly what to expect

during the test. Have them explain at each stage in the test what they

are doing and ask what they expect to see. Ask what measures the lab

takes to insure the accuracy of their measurements and test procedures.

Did they check their equipment today? Ask the test lab to let you see a

copy of the standard they are testing to and, while the test is in

progress, read it instead of sitting around waiting for results.

In any event, don't just

take a report with data as being good, try to validate the data if you

can by pre-compliance measurements or having a second test lab take the

same data. Failing a good product is bad enough, but passing a product

that in fact should fail is even worse in the long run and can cause

lots of business problems.

I am compiling more information and will have more to say at some

point, including recommendations for both test labs and designers

needing to have their products tested. For obvious reasons, I cannot go

into

detail on some of the above examples but if you want to discuss your

issues either as a designer with a product to test or a test lab,

feel free to contact me.

By the way, if you want to file a complaint against a test lab, this A2LA.org link may be useful. I am not aware of a link for a test lab to file a complaint against an unruly customer though.

Summary: Product

developers must be on the lookout when bringing their product in for

EMC testing. Asking a lot of questions and making sure the test

personnel understand how your equipment works can help to

get an accurate test. Having someone else look over the results is not a

bad idea either. "Trust but verify."

See my one hour webinar on this topic. Click here

to see a description of the webinar. This webinar is a real "eye

opener." Lots of information and checklists for both test lab customers

and test labs to protect oneself. "Trust but verify."

Links in this article:

A2LA.org A2LA test lab complaint page

NEW: Click here,

to see descriptions and registration information on my one hour

webinars than can solve difficult design problems quickly. Touching on

topics like signal integrity, EMC, ESD, and general analog and digital

design, these webinars are a quick way to get your design working.

There are public presentations every week as well as private

presentations on demand for as low as $40/person. New webinars are

added periodically.

Check

out my public seminar offering in Boulder City, NV. This is one of the

best seminar values around because the industry typical fee includes

more than just the seminar and lunch. It includes airport

transportation in NV, lodging in the historic Boulder City Dam Hotel and

Museum, and breakfast and lunch each day. Click here for more details.

The combination of the material presented, the venue, and the

passionate presentation will likely make for the best technical short

course/seminar you have ever taken! Didn't think a technical

presentation can be passionate,? This one is. The result is this short

course/seminar will likely be the most informative, practical, and FUN

seminar you can attend.

If you like the information in this article and others on this website,

much more information is available in my courses.

Click here

to see a listing of upcoming courses on design, measurement, and

troubleshooting of chips, circuits, and systems.

Click here to see upcoming seminars in Boulder City, NV.

|

Our office, laboratory, and classrooms are located in the

----------

Historic Boulder City Dam Hotel and Museum

1305 Arizona Street, Boulder City, Nevada 89005

Phone: (702) 293-3510

----------

Come

for a technical seminar, design review/troubleshooting, or just for a

visit and mix a little history of the Old West with your work!

|

|

|

|

Our Silicon Valley associate office and lab are located at

----------

NASA-Ames Research Center

RMV Technology Group

Bldg. 19, Suite 1073, M/S 19-46C

Moffett Field, CA 94035

|

Need help with a design or additional training on technical subjects? Click on the image below to go to

CircuitAdvisor.com, an engineering resource for training, news, and

fun. The site is being reorganized for group memberships and should be back up soon.

Click here for a description of one of my seminars titled (now also available online as a WebEx seminar):

EMC

Lab Techniques for Designers

(How to find EMC problems and have some

confidence your system will pass EMC testing while it is still in your

lab).

Top of page

Home