Abstract: Special precautions

need to be taken when measuring the current of a high voltage

discharge. A specially designed target that balances insulating a

current probe from the high voltage with minimizing inductance of the

discharge path is described. Construction details are given.

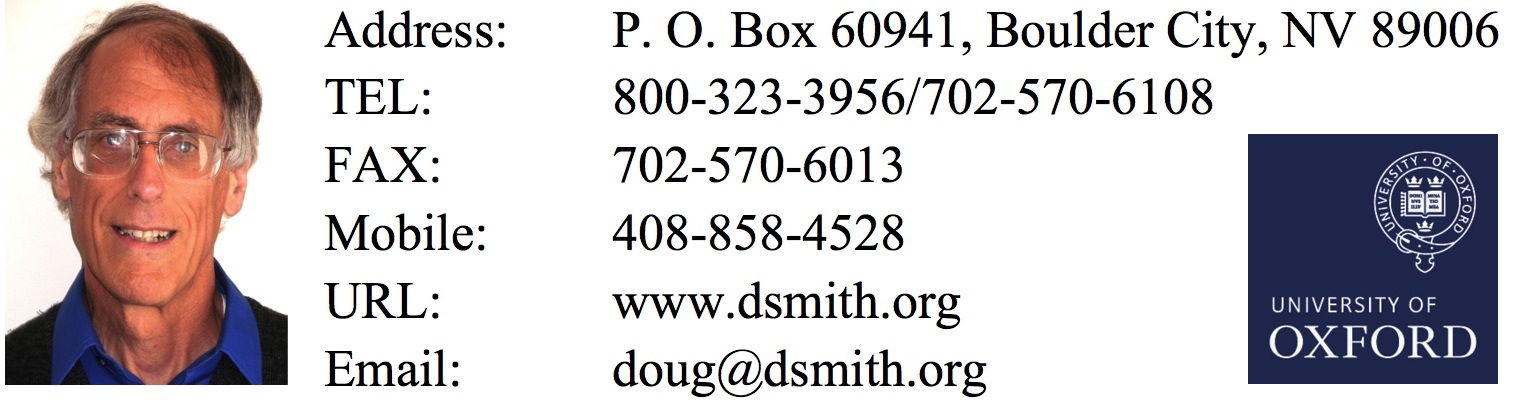

Figure 1 shows

an

overview of the target on the receiving end of multiple 50,000 Volt

discharges, mounted on a brass plate connected to earth ground. In trying to measure the discharge

current, I found it was difficult to prevent sparking over to the

current probe during my early attempts at this measurement, a more

elaborate test target was necessary. The parameters of interest were

insulation of the probe from the current path and the inductance of the

current path.

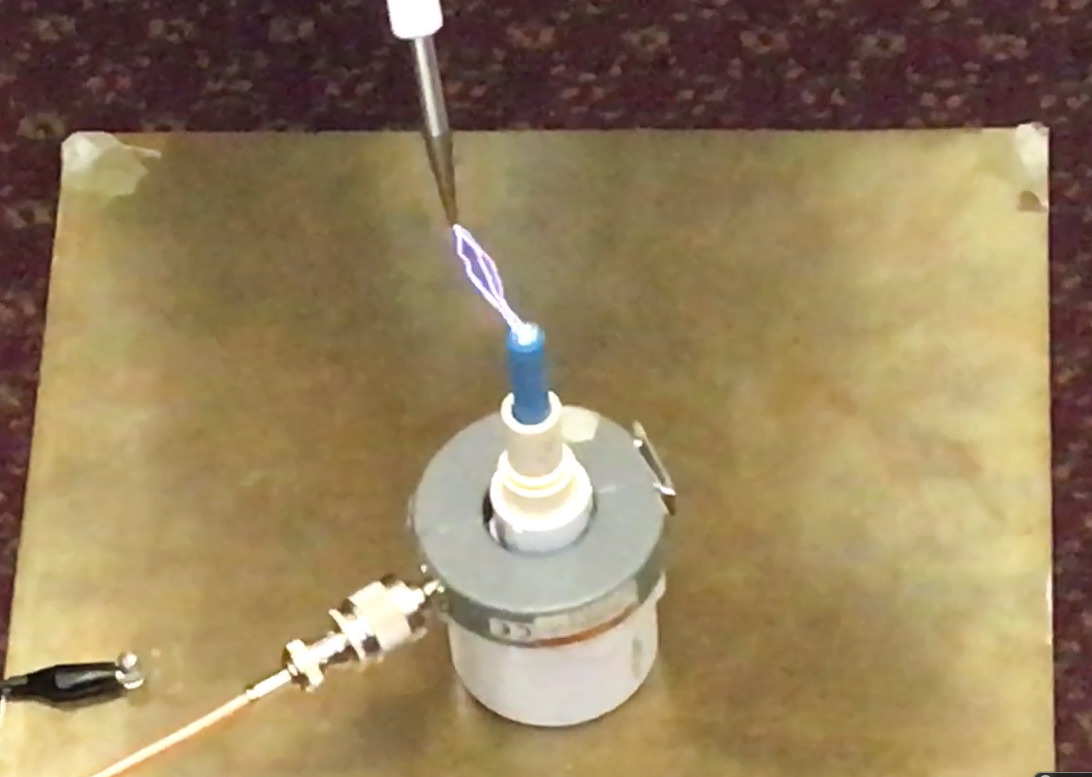

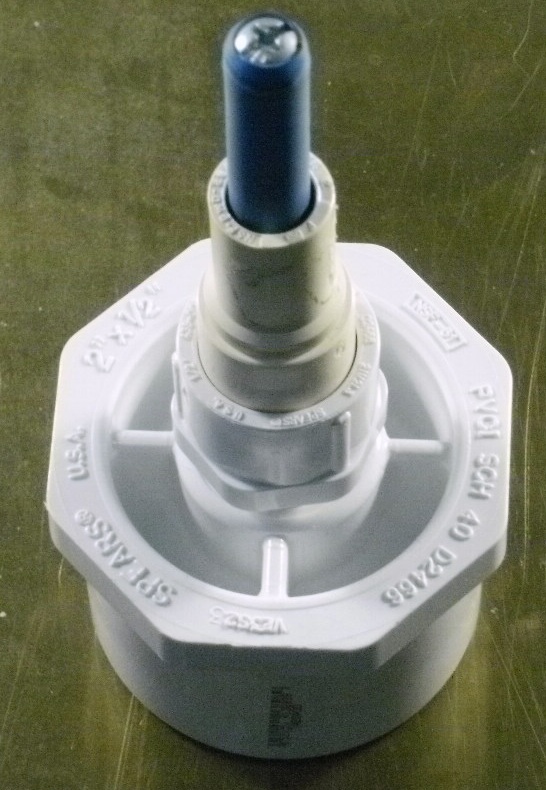

Figure 2 shows a close-up picture of the target. Its construction

consists of a 6 inch/15 cm length #10 screw (you can see the screw head

at the top of the target) inserted into a brass tube with a close fit.

The purpose of the brass tube is to reduce the inductance of the

current path due to its greater diameter and the lack of screw threads

on its surface. Skin effect will cause high frequency to have to travel

over the surface of screw threads, increasing the path inductance. Two

large washers with a center hole for a #10 screw were used on both

sides of the brass plate where the #10 screw passed through the plate.

This strengthens the fastening of the brass tube to the brass plate by

the #10 screw to avoid bending of the plate, screw, or the end of the

brass tube during lab usage.

The brass tube was then covered with four layers of heat shrink tubing

and then several plastic plumbing pieces fitted into each other were placed over the insulated brass tubing. The

bottom large plastic piece spaces up the current probe above the metal

plane, providing the required insulation against breakdown between the

plane and the current probe. The tubular upper parts of the plastic

pieces serve to center the current probe on the brass tube and to

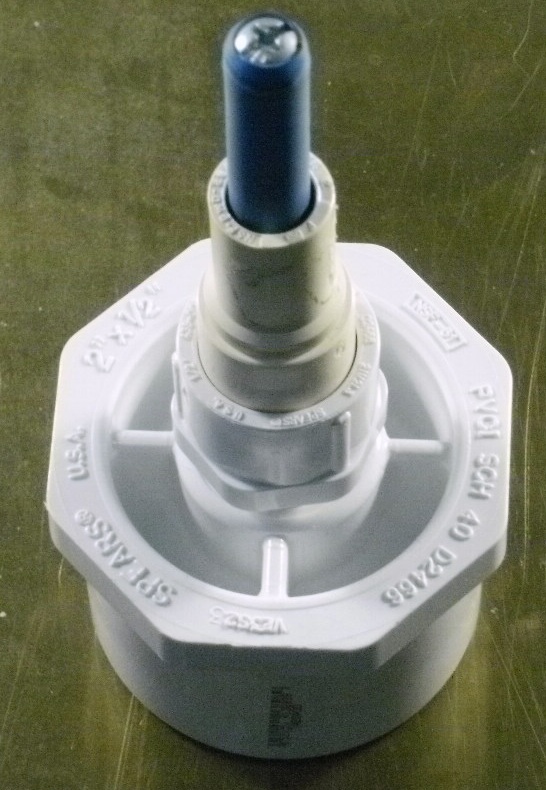

provide more insulation. This can be seen in the top view of the target

with current probe in Figure 3 and in the side view of Figure 4. The

current probe used was a Fischer Custom Communications F-65,

which is ideally suited to these kind of measurements due to its wide

bandwidth of 1 MHz to 1 GHz with flat frequency response.

Figure 2. Close-up of Target

Figure 3. Top View of Current Probe Centered in the Target

Figure 4. Side View of Current Probe in Target

This target worked well and allowed me to take a lot of data on high

voltage discharges which will appear later this year in a published

paper and on this website in support of a new method of ESD

troubleshooting and reliably finding dangerous failure modes. The peak current of the discharges shown in Figure 1

are approximately 50 Amperes measured with a 500 MHz bandwidth.